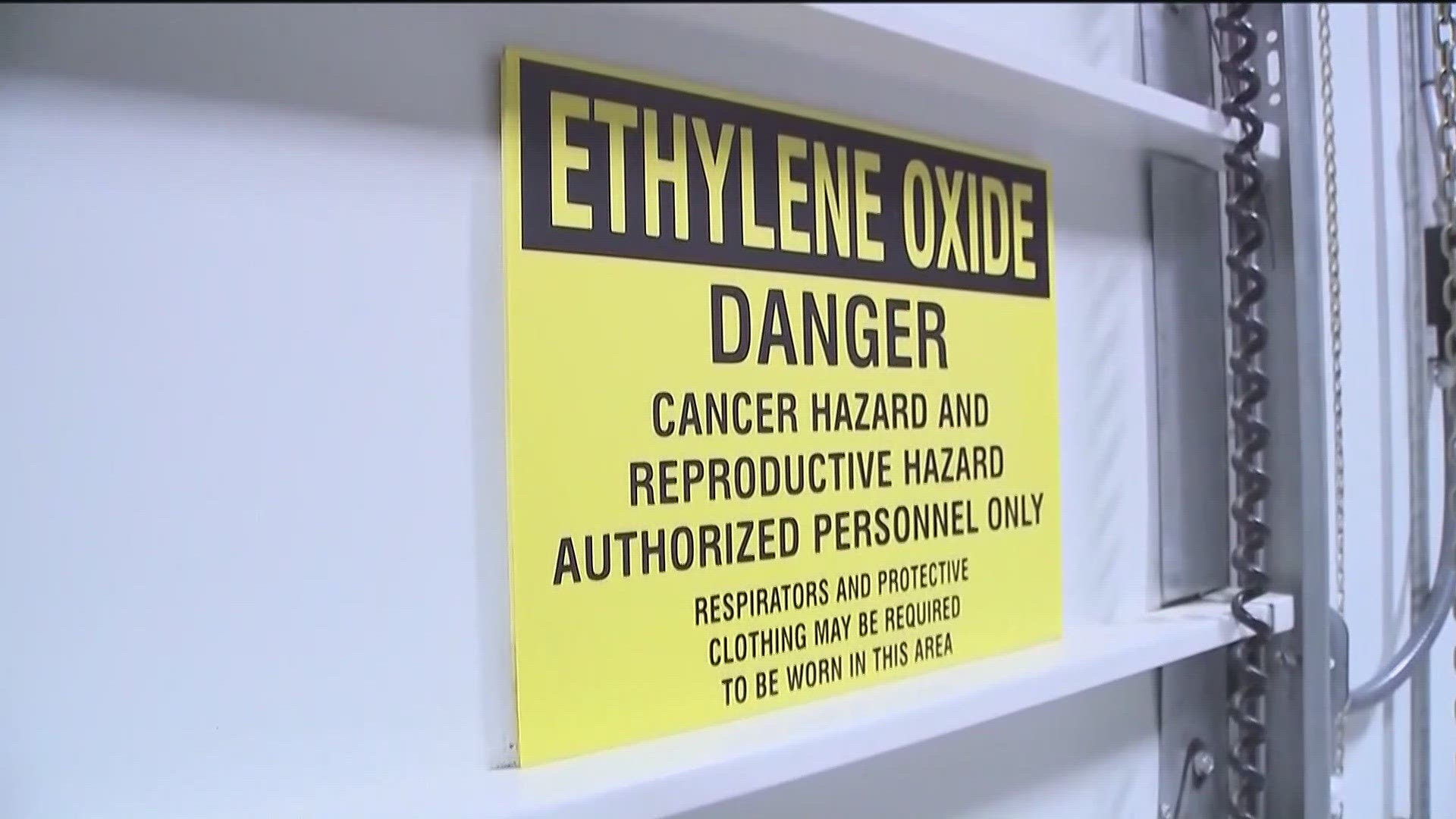

COVINGTON, Ga. — New rules proposed by the federal government could limit emissions of a cancer-causing gas into several communities around metro Atlanta.

The Environmental Protection Agency also wants to install monitors that would measure the output of ethylene oxide – which many residents suspect has spread illness in their communities.

Under rules proposed by the EPA, companies like Becton Dickinson in Covington would need to limit the output of ethylene oxide into the atmosphere or be in violation of federal regulations.

The companies use the gas to sterilize medical equipment.

In 2019, Jane Bledsoe told 11Alive she lived within a cluster of cancer patients behind a plant in Covington called BD. For years, BD has used ethylene oxide to sterilize equipment and emitted enough into the air to draw attention from state and federal regulators.

"There’s people all around here with cancer," Bledsoe said on her front porch in a community called Mill Town, adjacent to the plant property. "We’ve got cancer cases up that way on Wheat Street. I know of at least two people."

One of them was her husband Scott, who died of pancreatic cancer at age 51.

BD and Sterigenics in Cobb County contend their emissions fall within government guidelines and have caused no health issues. But the federal EPA wants to mandate levels that it said would cut emissions at all plants emitting ethylene oxide by 80% – and require real-time monitoring of air at plants to protect workers.

"The danger zone is within 10 miles. But definitely within two miles," said Michael Geoffroy, an attorney who lives a mile and a quarter from the Covington plant and represents clients who say the plant has harmed their health.

In a statement, BD said it has been modernizing its facilities and that “BD’s recent investments and innovations to reduce residual emissions… make our facilities well positioned to comply with any new final rules from the EPA.”

The full statements from BD and Sterigenics are at the bottom of this story.

Geoffroy said the EPA ought to be compelling companies like BD and Sterigenics to find alternatives to ethylene oxide to sterilize medical devices.

"The EPA is trying to get its arm around this problem," he said. "It’s a start and it's certainly overdue."

The EPA plans to hold public hearings on its proposed new rules for ethylene oxide in May. To learn more or to sign up to speak, click here.

BD sent 11Alive a statement in response to a request for comment on the proposed EPA rules:

BD takes our responsibility to provide critical medical devices to health care providers and patients very seriously, and ethylene oxide (EtO) sterilization is a necessary and required step for many of those devices to ensure patient safety. Equally as important is the health and safety of our employees, contingent workers and communities, and the robust controls in our facilities play an important role in minimizing emissions to levels significantly below what is required by the Clean Air Act. BD has been proactively investing in new innovations to further reduce emissions years before the new proposed rules were issued by EPA. BD’s recent investments and innovations to reduce residual emissions added to our long-standing focus and robust practices that ensure employee health and safety make our facilities well positioned to comply with any new final rules from EPA. It is important to note that our facilities in Georgia are within the EPA’s “acceptable risk” threshold.

It is important to understand the emission control equipment that BD uses to safely sterilize the medical devices that we manufacture. We use thermal oxidation technology in Georgia as our primary emission control equipment. These systems are hundreds of times more effective at reducing EtO emissions than what is currently required under the Clean Air Act. All sterilization chambers operate under a vacuum and all air from the sterilization and aeration chambers (including back vents) gets routed to the primary emission control equipment. After sterilization is complete (including multiple aeration phases) there are trace residual amounts left in the packaging. The residual amounts are below the requirements set by the U.S. Food and Drug Administration (FDA) to ensure safety of health care providers and patients. These residual emissions (EPA calls them fugitive emissions) are the source of the majority of emissions from BD facilities and are not currently regulated by EPA. Over the last few years, BD has voluntarily innovated and installed new capture and control systems to further reduce these emissions. These are known as “dry bed” systems that are able to absorb low levels of EtO from the air. Those systems were installed in both our Covington and Madison facilities in 2020 and have proven to reduce residual emissions by 90% to 95%.

One thing that is very important for people to understand is the levels of EtO in the air near our sterilization facility and how that compares to areas that don’t have a sterilization facility near them. Interestingly, Georgia EPD has collected more ambient air data regarding EtO than anywhere else on the planet (that we know of) and the data show that the level of EtO in the ambient air in Covington is about the same or lower than where there are no industrial uses, including the rural General Coffee State Park in Georgia. It also shows that EtO levels in Covington are lower than most areas of the United States, based on EPA reported measurements.

Sterigenics sent this statement in response:

“Sterigenics consistently complies with environmental permits issued for each of its sterilization facilities and has a track record of continuously implementing leading safety practices and the best available EO emission controls, going beyond regulatory requirements to further improve our already safe operations. We are confident that our on-going investments will continue to demonstrate our leadership in safety and EO emission control.

“Sterigenics supports EPA’s mission and is firmly committed to regulation based on sound science. Unfortunately, the EPA’s draft proposals rely on a flawed IRIS risk assessment that overstates actual risks related to EO levels found in everyday air and also contradicts real-world findings from the NIOSH study of actual sterilization facility employees which showed “no overall elevated risk for any type of cancer.” The use of EO for the sterilization of medical devices is essential to the U.S. health care system and Sterigenics looks forward to continuing to collaborate with federal and state regulators for the safety of our employees, the patients we serve and the communities in which we operate.”